Introduction

Smart grid is the integrated power network with intelligent power generation, power transmission, power distribution, and users established via information, communication, and automation technologies. It put emphasis on automation, security, and close coordination between user end and supply end in order to enhance power system operation efficiency, power supply quality, and grid reliability.

Taipower’s policy of promoting “Smart Grid” is based on the “Smart Grid Master Plan” approved by the Executive Yuan on September 3rd, 2012. This plan consists of four major aspects of power generation and dispatch, power transmission, power distribution, and user. “Smart Meter” is associated with the Advanced Metering Infrastructure (AMI) project developed under the “User Aspect”. It is mainly composed of smart meter, communication module (including communication network), and meter information management system. In addition to recording user power consumption situation, and periodic feedback of meter data, it can also replace the manual meter reading.

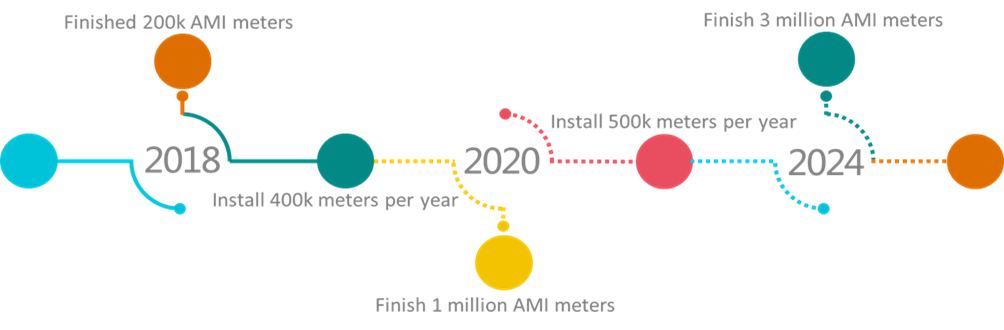

Taipower has completed the deployment of AMI for nationwide high voltage (and above) users (about 24,000 households) in 2013 to be aware of 60% of power consumption in the entire country, and the demonstrative preliminary installation of 10,000 households of low voltage AMI has been completed in 2015 in order to identify various problems as early as possible and to come up with solutions. During the installation period, the complicated building environment in our country and the factors of communication technology and laws and regulations resulted in poor communication (for example, if the building density is high or if the meter is located in the basement or wireless communication dead corner, only the public frequency band of 2.4GHz is available. The transmission distance is rather short, and it is vulnerable to existing communication and environmental impacts. Thus, we could not adopt specific communication technology for deployment just like other foreign countries) and compromised deployment effectiveness. Therefore, we conducted several reviews with Bureau of Energy, MOEA during 2015~2016 and dedicated to take the steady approach of promotion in phases based on the principle of completely solving the communication obstacle during actual practice. And the “Modified Plan for Subsequent Promotion of Low Voltage AMI” was reported to the Bureau on July 28, 2016. According to the “Low Voltage Smart Meter (AMI) Promotional Plan” approved by the 3515th Council of the Executive Yuan for future reference on September 22, 2016 and the amendment of “Smart Grid Master Plan” approved on February 18, 2017, Taipower will set the power saving potential users as the deployment targets, and the deployment low voltage AMI Smart Meter of 200,000 households must be completed in 2018, the accumulated deployment of 1 million households will be completed by 2020, and the accumulated deployment of 3 million households will be completed in 2024.

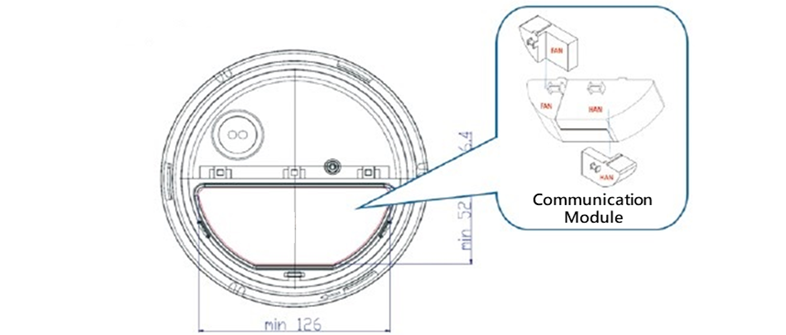

In order to successfully promote the installation of low voltage AMI smart meter, Taipower conducted the research on “AMI Communication Module Evaluation Mechanism and Applicable Technologies” and upgrade the communication module of AMI meter to the pluggable design in order to prevent communication module from being tested and sealed within the meter, thus causing the difficulty in future replacement of communication module (the entire meter must be replaced, thus leading to impact on user power consumption and the increased cost). As a result, the meter maker can be more focused on the R&D of meter technology. In response to our government’s cultivation of domestic AMI communication industry, the expectation is to bring more communication service providers to help with AMI deployment. However, Taipower takes into consideration the rapid advancement of AMI communication technology. In addition to ensuring that it will not be limited by any single communication technology provided by communication service provider, the different communication technologies deployed in subsequent stages of low voltage AMI must be compatible with meters of different brands. Therefore, Taipower will first identify the AMI communication technology suitable for our country, and the large-scale deployment will be conducted based on the obtained results.

In summary, in order to overcome the issue of poor communication in our country due to the factors of complicated building environment, communication technology, and laws and regulations, Taipower has conducted the low voltage AMI smart meter deployment via the separate tendering of meter, communication, and meter data management system. The communication module of meter is upgraded to the pluggable design. In addition to bringing in more meter and communication service providers to help with AMI deployment, it can also take care of the communication upgrade and successful interfacing of meter data management system. Therefore, Taipower has conducted the low voltage AMI smart meter communication evaluation mechanism, and the communication technology tests have been conducted via meter installation at the site or in the laboratory to select qualified communication service providers to help with AMI deployment in our country. In addition, Taipower has also actively requested the 839~851MHz public industry communication exclusive channel with better penetration from our government. In July 2018 our government officially approved the use 839~847MHz public industry communication infrastructure exclusive channel with better penetration, which would contribute to Taipower’s large scale deployment of low voltage AMI in the future.

System Architecture

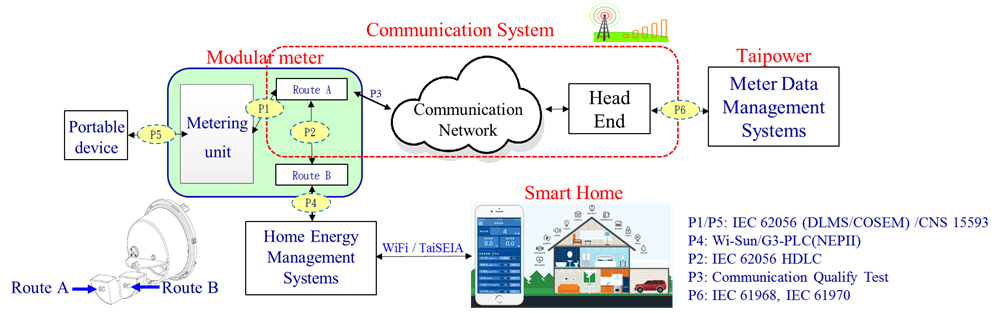

Taipower learned a lot from the experience of the AMI deployment of low-voltage customers pilot program (about 10,000 customers) and try to apply more modularized, standardized method for now (two hundred thousand to three million customers) and future deployment. The aim is to wisely deploy, well maintain and support more innovative applications. The system structure of AMI is shown as Figure 1, including smart meter, communication system and meter data management system (MDMS).

The buildings in Taiwan are mostly apartments. In order to cope with the bottle neck of communication, the innovative pluggable dual-communication module has been launched. Route A can access the data or events from metering unit through P1 interface and communicate with head-end server through P3 interface (wide-area communication network). Each head-ends will send information to MDMS in Taipower through P6 interface. Two types of communication module (wireless Wi-SUN and wired PLC) have been applied to deal with different on-site situations. The modules are optional according to the communication quality test of concentrator.

On the other hand, Route B has been kept for offering an on-demand channel for customer to access meter data directly, which can open the probability of HEMS (Home Energy Management System) application. Wireless or wired type of communication module is also optional due to customers’ switchboard. Smart meter in AMI is not only a point of common coupling between customers and utilities, but also brings in new data applications through Route B (P2/P4).

Considering maintaining and applications, IEC62056 series has been used as the protocol for communication application layer. The meter also support firmware update mechanism, can be interoperable with the pluggable dual-communication module.

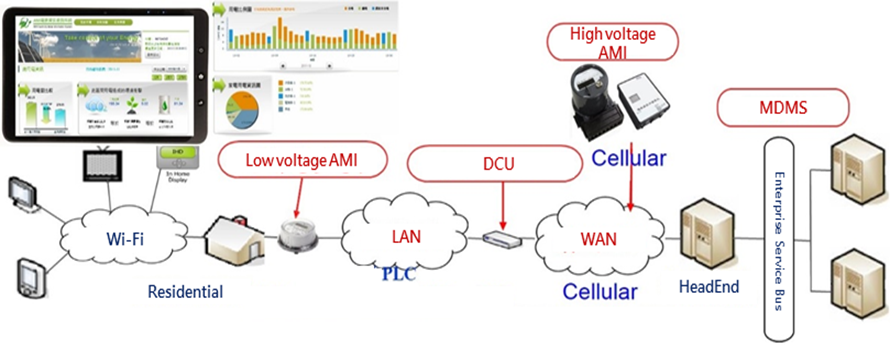

The smart meter system architecture planning must ensure data security, reliability, and privacy. It can be divided into four parts of user, meter, communication network, and meter data management center. With the communication backbone, the meter data can be sent back to the utility or serve as users’ reference via ICT for relevant applications. Our company completed the installation of high voltage AMI smart meter in 2013. Now we are in the process of installation of low voltage AMI smart meter, so the evolution of low voltage AMI smart meter will be described here.

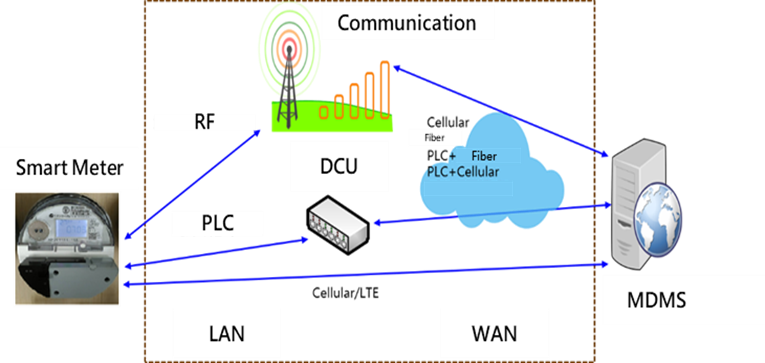

Low voltage AMI smart meter communication network can be divided into the two parts of LAN (Local Area Network) and WAN (Wide Area Network). The adopted communication technology is as described below:

- LAN:Different technologies, such as wired or wireless communication, are adopted in response to different environments (such as collective residential building and distributed housing community).

- WAN:The area with higher construction benefit will have the priority of construction and the consideration of incorporating our company’s feeder automatic fiber optic plan.

The promotion of greater scale must take into consideration of the construction schedule of incorporating our company’s feeder automation or renting the network of telecommunication operator in order to seek the plan of lower cost.

Renting the existing mobile communication network to serve as the data upload path can achieve the advantages of quick deployment and low installation cost, yet there is a constant communication fee for the future operation. In addition, there are the issues of coverage rate and communication dead corners of wireless communication, so the communication quality measurement must be conducted before the selection of deployment sites.

According to the plan approved by the Executive Yuan, our company completed the 10 thousand households low voltage AMI installation project in 2012. In this project, the data of multiple meters was read via RF or PLC technology by using concentrator or receiver (AP), and it was sent back to the control center via optic fiber or mobile communication. So, the communication network is the key to its reliable operation. So, this deployment (early stage) could be used to set the deployment speed, the technical capability of installation personnel, and the integrity, stability, and compatibility of the entire system in order to find problems as early as possible and to come up with solutions.

The experience of the installation of this demonstrative project revealed that the actual deployment was limited by the installation location of communication equipment, complexity of onsite environment, the lack of exclusive frequency band, laws and regulations, and local customs. As a result, the communication calibration after deployment took a lot of time, thus resulting in schedule delay and significantly increased operation and maintenance cost. Therefore, the issue of communication technology must be solved before the large-scale low voltage AMI can be effectively deployed in the future.

In order to solve the communication problem of the installation of demonstrative project, our company carried out the research project of “AMI Communication Module Evaluation Mechanism and Applicable Technology” in 2016~2017. Considering the long-term promotion AMI, it can be divided into low voltage AMI meter, communication system, and meter data management system (MDMS). And all interfaces are re-defined. The flexibility of AMI communication selection is to be maintained via “Communication module upgraded to pluggable design” in order to find the communication technology most suitable in the environment of our country.

Based on AMI communication evaluation operation, our company can conduct document review operation, experimental field test, and test and evaluation of communication technology with respect to the communication system manufacturers participating in the evaluation. So that communication system manufacturers can conduct initial test of communication environment, reduce the impact of building density and the number of meter collection, excluding the limiting factor of installation site of concentrator, clarifying the source of PLC communication technology interference, and improve the communication dead corner. In 2017 there were a total of 5 manufacturers which passed the communication system evaluation and participated in the procurement project of communication system of our company, and now increase to 7 manufacturers. They used the communication technologies passing the evaluation test according to the procurement regulation to help our company deploy low voltage AMI smart meter.

MOTC announced on July 16, 2018 that 839~847MHz could be used for smart meter reading system of livelihood public business, and our company was provided with exclusive frequency band for large scale deployment of low voltage AMI smart meter. Considering the rapid development of communication system, our company will continue to conduct AMI communication evaluation operation. For our company, the communication technology qualified by the evaluation can ensure the stable communication of installation of AMI smart meter in response to the development and evolution of communication system.

Deployment Schedule

Taipower has installed AMI meters for large (all extra-high-voltage and high-voltage) customers in 2013. For small (low-voltage) customers, Taipower plans to install up to two hundred thousand, one million and three million AMI meters in 2018, 2020 and 2024 respectively. The schedule was approved by Executive Yuan in September 2016.

There are more than 14 million electricity customers supplied by Taipower. Even if finishing 3 million small customers’ AMI deployment in 2024, the penetration of AMI users is only about 21%. However, the power usage of large-scale customers with installed AMI are about 60%, after finishing 3 million customers’ AMI deployment in 2024, Taipower could handle around 81% of power usage information of Taiwan’s power system.

Taipower conducted low voltage AMI smart meter deployment via separate tendering of meter, communication, and meter data management system. The current status of deployment is as shown below:

Meter

The procurement of 200,000 units of low voltage AMI smart meters was completed in 2017.The accumulated installation of 230 thousand smart meters was completed in 2018 and 600 thousand smart meters in 2023. Last year Taipower has deployed about 2.7 million smart meters for commercial and residential customers, which occupies about 79.2% of all customers’ power usage in Taiwan.Communication module

The procurement of 200 thousand units of communication modules was completed in July 2018. The installation of 230 thousand communication modules was completed in March 2019. In 2023, we have installed about 2.7 million communication modules. The total system connection rate between MDMS and smart meter is over 97%.Metering data management system (MDMS)

Metering data management system (MDMS) has been on-line system in 2020, and it can successfully collect and manage 1.8 million meters data.

MDMS Data Interfaces & Service Applications

Along with the schedule of AMI deployment, Taipower is planning to construct a MDMS (meter data management system) which can accommodate with some millions of customers’ AMI data.

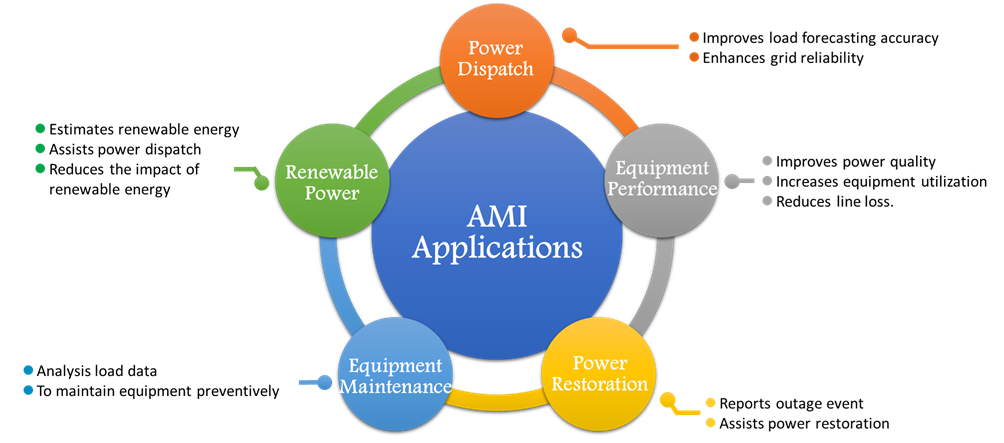

MDMS is extremely important in the architecture of AMI. It should be able to offer processed data, which is consistent and can be directly used by other applications, to make sure the applications can be integrated on the same basis. The repetitive data pre-processing work (ETL, Extract-Transform-Load) can also be avoided. MDMS can help earn valuable application by providing good data, related application such as power dispatch, renewable energy, equipment performance, equipment maintenance and power restoration, shown as figure below.

The applications mentioned above are essential subject for different domains to promote their business. For example, billing system, demand response (DR), outage management system (OMS), distribution assets management, etc. In the meanwhile, customers’ AMI information can be provided to ADMS (Advanced Distribution Management System), or system operators for reliable dispatch (with renewable energy) by implementing big-data analytics.

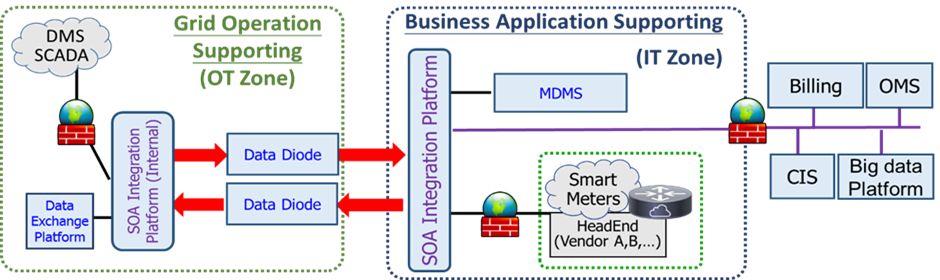

For long-term operation, MDMS adopts SOA (Service Oriented Architecture) as interface standard, which could realize CIM (Common Information Model), to connect IT (Information Technology) and OT (Operation Technology) system, shown as figure below.

MDMS in Taipower is about to complete in 2020, which will lead to various applications on demand/distribution side, that accommodates renewable energy penetration and enable electricity trading for future deregulated market in Taiwan. Big-data applications focusing on meter data will also make great contribution on promoting sensational customer service and innovative business model.

Taipower’s Meter Data Management System (MDMS) is based on the Energy IP products of the industrial leading brand Siemens established on the Vmware Software-Defined Data Center (SDDC) platform. The entire information infrastructure is equipped with high expandability and availability. The short-term target of total amount of AMI deployment is 3 million units. It is expected that MDMS should be able to successfully adapt to and accommodate the aforementioned meters, and it should be able to successfully support the future expansion to 6 million or 14 million units of meters.

To avoid being locked on one single product, the Taipower’s MDMS can be interfaced with Headend equipment produced by different makers in accordance with the IEC 61968-9 CIM standard. As a result, it can greatly reduce AMI deployment cost and the supply risk. In addition, the Enterprise Service Bus (ESB) provided by Green Bird has been incorporated between MDMS and Headend in order to receive the huge amount of AMI data of meter reading and event at the site. The ESB is built on the latest cloud platform technologies such as Kubernetes and Container so that it provides sufficient data buffer, high speed data format conversion, and the highly scalable processing unit capability.

For the purpose of high speed processing of AMI meter event data for real-time support of quick malfunction block identification of Advanced Distribution Management System(ADMS) and reduction of the number of power outage cases accepted based on users’ calls, the Streaming Platform of IBM has been incorporated at the rear end of ESB in coordination with the distributed search technologies (such as Elasticsearch and Kibana) to conduct power outage streaming analysis and to ensure the real-time data processing of meter event. Now customers can see the latest 5 hours ago power consumption data through Taipower’s mobile APP.

In addition, to ensure that the MDMS data in IT zone can be exchanged with ADMS in OT zone, Taipower uses two Data Diodes to integration of IT ESB and OT ESB for the purpose of highly cyber security. When the MDMS transfers data from IT zone to OT zone, it must pass through security protection such as content filtering to ensure the data exchange between MDMS and ADMS under the safest protection.